Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Cut through metal like a pro—don’t get left behind on precision and power!

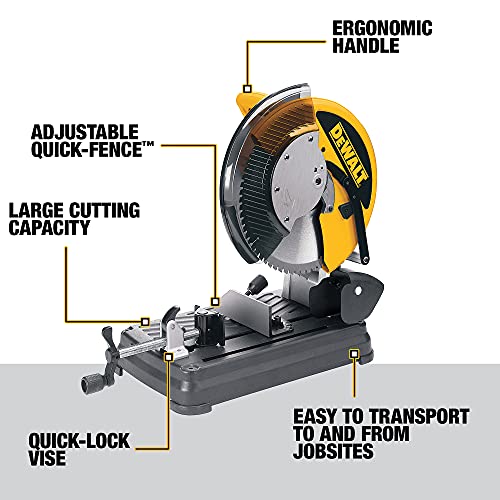

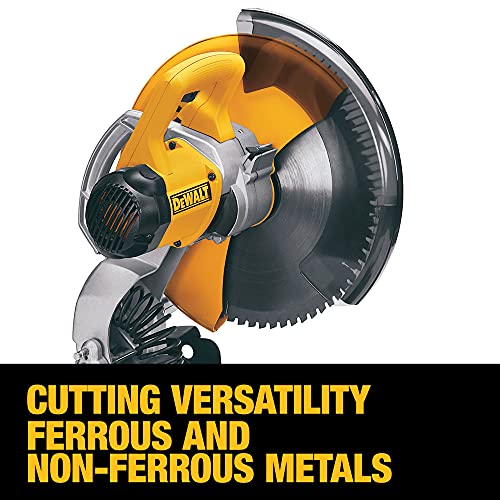

The DEWALT Heavy-Duty Multi-Cutter Saw features a powerful 15 Amp motor paired with a 14-inch carbide blade spinning at 1300 RPM, delivering clean, precise cuts on metal up to 3/4" thick. Designed for professionals in welding and fabrication, it offers versatile 45° miter cutting and a spindle lock for easy blade changes. Its robust build and consistent performance make it an essential tool for saving time and enhancing accuracy on demanding job sites.

| ASIN | B0000302QS |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #829,864 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #96 in Power Metal-Cutting & Chop Saws |

| Blade Length | 14 Inches |

| Blade Material | Carbide |

| Blade Shape | Round |

| Brand | DEWALT |

| Color | Dewaltâ Yellow and Black |

| Customer Reviews | 4.4 4.4 out of 5 stars (650) |

| Cutting Angle | 45 Degrees |

| Date First Available | December 13, 2006 |

| Global Trade Identification Number | 00028875008723 |

| Handle Material | Metal |

| Included Components | Bare Tool |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 55 pounds |

| Item model number | DW872 |

| Manufacturer | Dewalt |

| Number of Teeth | 70 |

| Part Number | DW872 |

| Power Source | Corded Electric |

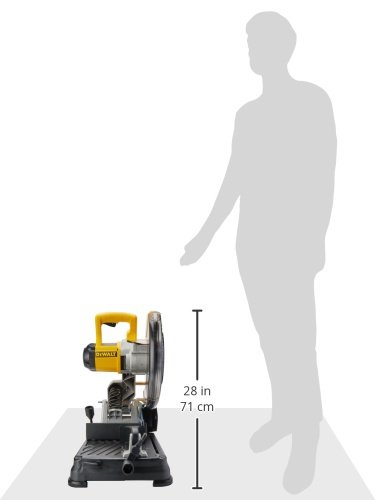

| Product Dimensions | 24"L x 18.5"W x 15.25"H |

| Size | 14 Inch |

| Special Feature | Spindle Lock |

| Special Features | Spindle Lock |

| Speed | 1300 RPM |

| Surface Recommendation | Metal |

| UPC | 799360178985 028875008723 |

| Voltage | 120 Volts |

| Warranty Type | Manufacturer |

| Wattage | 1800 watts |

S**Y

Like a hot knife....

I've tried it all, bandsaw, handheld plasma cutter, 14" grit saw. All in the attempt to make accurate cuts in 1/2" x 6" hot rolled bar stock. All were pathetic attempts. In frustration I bought one of these saws. Cutting very slowly at first, as that's what I read online was the 'right' way. I spent just over 7 minutes per. After a few of those I started to get impatient, I realize solid stock this size is approaching the limits of the saw blade, so decided to 'sacrifice' the blade in the interests of finishing the job before I retire. Adding just a little downward pressure improved things dramatically. Not hanging from the handle, but just a little more than the weight of my hand and cut time went from 7 minutes to 1. Cut quality is excellent and accuracy is as good as my setup of the saw/fence. No blade deflection, no dross on the bottom of the cut, just clean and ready to weld. I will say that with stock this wide and flat the chips do get hot and sparks are flying. The teeth spend a lot of time in this sort of cut, I couldn't get the material too far forward as they suggest in the manual. That seems to be the nature of the beast in this case. Cutting smaller stock and things stay cool and no significant sparking. Can't speak to how long the blade will last before resharpening or replacing but after a couple hours of this continuous use as described, no significant difference in cut time or quality (yes a little bit, but not significant). I'm sure the blade is getting duller and the heat is affecting the carbide, but the effect is subtle and perfectly reasonable. And that's with the 'free' blade that comes with it. Likely a high quality aftermarket blade with better carbide will be even more impressive. Best of all, unlike grit disc saws, no smoke and grit cloud to breath. Downsides: The fence is light for my use. The angle shifts as I push the bar stock around to square it up to the fence, on occasion pushing the fence to the bar rather than the other way around. I'd like to see a more positive lock on that. After-all, metal heavy, no? I'd also like to see accurate and adjustable positive stops for the common angles. The stamped marks are useless, why bother? Do it right or leave them off all together. I'd like to see variable speed. I got the feeling that the fixed speed was a bit faster than wanted for such a long time in the kerf. Again, maybe my project is pushing the boundaries, I can see with thin wall material slower would be bad. The work piece clamps work OK, I'd like to see the pivot on the main clamp be lockable so it can secure small work pieces without pivoting or having to add spacers. Just a pin to lock it square would be great. Overall, it's a great saw, buy one and be happy.

M**1

Great time saver.

I received my saw on the day that Amazon promised. The Packaging was damaged in a couple of places, but the product was not damaged. I also ordered an extra blade, because this blade is not found at the local hardware store. Lowes can order them, Amazon had mine in 2 days. I use my saw on an industrial job site. I'm in a business of pipe and structural welding. We have made numerous repetitive cuts, such as flat bar from 1/8" to 3/4" thickness, small bore pipe, and angle iron. This saw saved tons of man hours and money compared to a welder with oxy/acet torch. It makes smooth straight or miter cuts, with no clean up time. It is also great for miter cuts on building hand rails and structural projects. I would highly recommend anyone that is working in a welding shop or job where you need a saw that is versital and portable, should try this saw. I want to give some safety precautions with this saw. It does throw sparks from the product you are cutting, wear all of the proper PPEs that are described in the booklet provided and keep all flammable away from work area. Also, don't rush the cutting process. Let the saw do the work, do not force the cut. GREAT product!!!

G**P

Awesome saw for the money!

I highly recommend this saw. It's on the user to set up the material properly. Take the time and make a couple supports if you're cutting long stock. My saw deck sits roughly 3 3/8ths above the table, so I made supports that height. I bungled up the blade a little on my third cut (it'll knock the carbide tips right off) by not having the piece secured and supported properly. Now my saw blade is slightly imbalanced and it vibrates a little - my fault, not the saw's. You can damage the blade, motor, and shaft if you put it in a bind. Take your time in the set-up and clamping. You'll get awesome cuts and the blade will last a long time. The vice isn't the best like others have said, but if you take your time and check for square before cutting you'll be fine. Cutting 45's is a little tricky- just have a good triangle square on hand and don't hurry. Gloves and safety glasses or a face shield are a must - don't scar your eyes up with metal shavings. I paid 400 for this saw shipped FREE to Alaska tw years ago. It's still a great deal. The lowest I've seen it in the stores up here was 450.

D**L

Works excellent powerful and the blade cuts awesome, I'll never use the cheaper cutting blades again.

C**R

Es una cortadora excelente, no te cansas ya que soy jobista y no estoy acostumbrado a estar corte y corte materiales con el arco. Si pesa algo para transportarla, pero de ahí en fuera te ayuda bastante. Hice varios cortes a un ángulo de acero de 4"x3"×0.25" y fue super rápido y nada cansado. La agarre de oferta x eso me anime a comprarla para mis proyectos personales. Un 30% menos de 11k con las promociones de las TDC.

J**V

pros: - corta super rapido y sin necesidad de estar cambiando discos, llevo mas de 1000 cortes de metal y sigo usando el mismo disco que traia. - cortes a 90 y 45 los hace perfectos (aunque no confies en las marcas que trae la cortadora, usa tu propia escuadra para calibrar los cortes) - corte en frio, lo que significa que el material no se dobla por calor y puedes manejar la pieza tan pronto termines de cortar. - no suelta nada o casi nada de chispas (dependiendo la vida de tu disco) entonces es menos de peligro de fuego en talleres. - el disco aguanta vara... al inicio no sabia como usarla bien y me fregue 3 dientes de los 66 del disco, llevo muchos cortes despues de eso y sigo cortando sin problema. contra: - es CARA, a comparacion de una convencional de abrasion o una segueta, pero en mi opinion vale la pena si haras muchos cortes. - tienes que tener en cuenta las vibraciones, si no tienes tu pieza bien sujetada por ambos lados (sujetada con la mano no es posible ni recomendado) tu disco se puede dañar y puede ser peligroso ya que te avienta la pieza con mucha fuerza. - la rebaba que avienta es filosa, mas que las chispas de una de abrasion entonces es recomendado usar una careta en vez de solo lentes de seguridad. mi experiencia con esta cortadora desde que la compre es que la empeze a usar como si fuera una de abrasión, aplicando presion en la pieza y no sujetando bien la pieza por ambos lados, grave error ya a esta cortadora no se le puede hacer tanta presión como las de abrasion, tambien me fregue 3 dientes de el disco (los cuales son caros! +2000$) pero despues de ver unos videos de como usarla bien y seguir usandola, llevo mas de 1000 cortes en metal con el mismo disco y sigue con madre! si tienes un taller o te importa mucho como quede el corte de tu pieza 100% recomendada.

G**.

Coupé acier et aluminium . Repère d’angle pas assez précis à mon goût il faut verifier avec équerre et se faire une marque

J**T

Real Torquey on startup, occasionally trips a breaker if you grip the switch tentatively. Clamp your parts securely. Expect to sweep a 10 foot radius. The guide isn't in any way precise. Resulting angles are approximate. Works best on profiles with wall thickness less than a quarter. It'll do half-inch aluminum flat bar, but I find the metal-cutting band saw to be better-suited for that. I've worked mostly with aluminum. Occasional Steel.

Trustpilot

2 months ago

1 month ago