Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Elevate your DIY game with copper that means business!

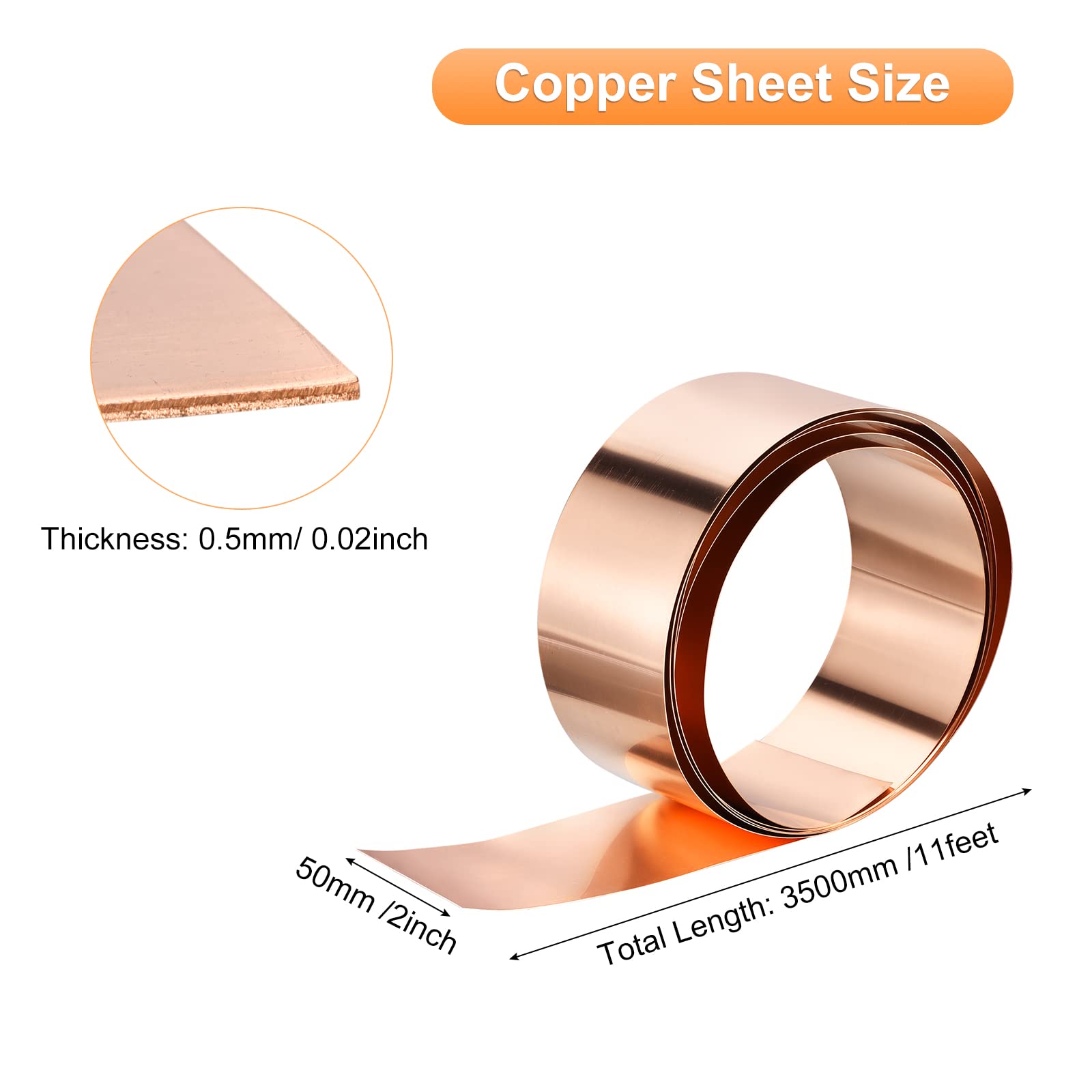

The uxcell Copper Flashing Roll is a 0.5mm thick, 11ft by 2in pure copper sheet designed for professional contractors and DIY enthusiasts. Crafted from 99.95% pure copper, it offers superior corrosion resistance, excellent thermal and electrical conductivity, and easy bendability for custom roofing, flashing, and craft projects. Its weatherproof durability ensures reliable performance in harsh outdoor conditions, making it a must-have for high-quality construction and creative applications.

| ASIN | B0C55K9TT4 |

| Best Sellers Rank | #96,468 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #8 in Roof Flashings |

| Brand | uxcell |

| Brand Name | uxcell |

| Color | Red Copper |

| Colour | Red Copper |

| Customer Reviews | 4.7 out of 5 stars 61 Reviews |

| Grade Rating | Commercial |

| Item Form | Roll |

| Item Shape | Rectangular |

| Item Thickness | 0.04 Inches |

| Item form | Roll |

| Item thickness | 0.04 Inches |

| Manufacturer | uxcell |

| Material | Copper |

| Shape | Rectangular |

| Unit Count | 1.0 Count |

A**R

Merci

Merci

B**U

Good quality.

Fair price. 0.5mm thickness is still quite heavy!

C**P

sculpture artist's dream

The gauge was perfect. Exactly what I was looking for. Was clean, no scratches. Annealed like a dream. Will make my sculptures easier. Now I have a good source of copper!!! .

J**N

Clean raw copper packaged as a very tight diameter roll

Product is as described and overall good quality raw clean copper sheeting. Challenge is that it's packaged as a very tight diameter roll (roughly an inch overall), so un-rolling to get something resembling straight is hard. If you need just something "industrial" and don't mind how it looks, this can be perfect. If you want to use this for something that needs to look clean and nice, I'd try finding something that's packaged less efficiently.

S**8

Works great to replace sections of PCB traces

I have a system board I'm repairing after cap leak damage. there was a 3/4 inch section where the traces and pads from SMD components were eating away by the electrolytic. I tried a few things, but this was is the right thickness. I traced out the design I needed, cut it out with a pair of small scissors and then used some epoxy to put the new piece on the PCB. I'm still looking for a better epoxy, as the heat from the soldering iron cause the epoxy to melt, but one I'm done soldering the epoxy re-hardens so for now it is a workable solution.

Trustpilot

2 months ago

2 days ago