⚙️ Upgrade your Jeep maintenance game—service smarter, not harder!

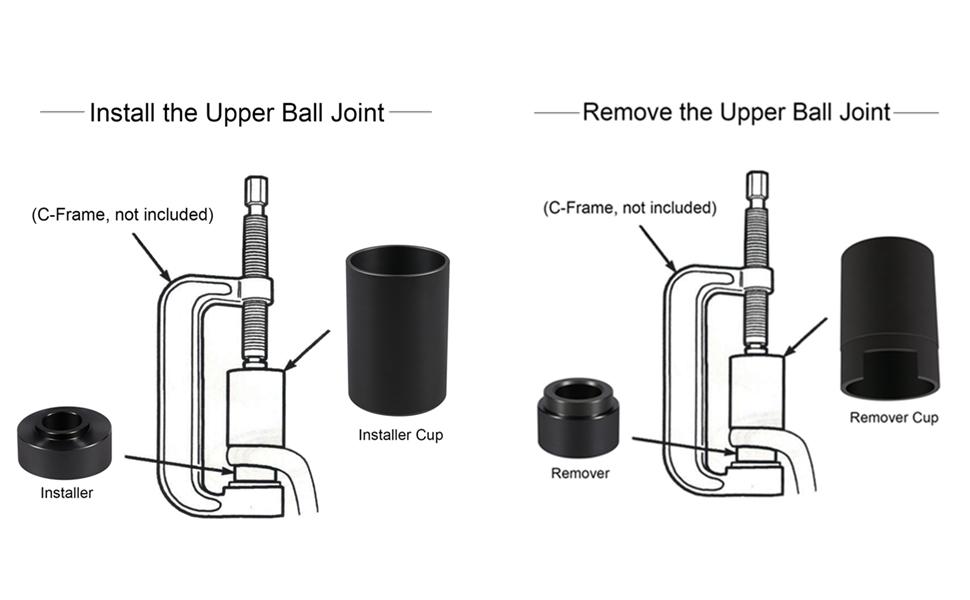

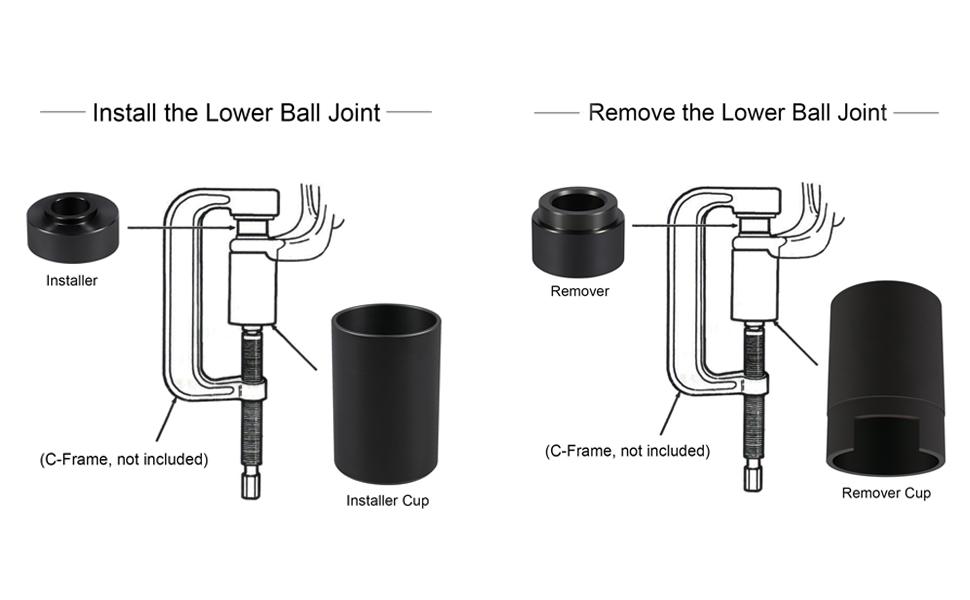

The Sunluway Ball Joint Service Adapter is a precision-engineered tool kit designed for quick, safe removal and installation of press-fit upper and lower ball joints on 1984 and newer Jeep and Dodge 4WD models. Made from corrosion-resistant steel, it features specialized adapters that eliminate the need for washers or shims, enabling a flawless fit and reducing service time to just 10 minutes. Backed by a 30-day satisfaction guarantee and 12-month warranty, this kit is a must-have for professional-grade vehicle maintenance.

| Manufacturer | Sunluway |

| Brand | Sunluway |

| Product Dimensions | 11.43 x 6.35 x 6.6 cm; 1.4 kg |

| Item model number | 13 |

| Manufacturer Part Number | XXl5026 |

| Item Weight | 1.4 Kilograms |

S**E

Time saver

Time saver. No issues . Strong

J**9

EXCELENTE PZA

LO FACIL DE EXTRACCION Y INSTALACION

A**R

Perfect for my 2013 Jeep Wrangler JK (2007-2017 JK’s)

I was apprehensive about purchasing this kit after reading a few of the negative reviews, but decided to pull the trigger anyways.I was pleasantly surprised! This is a must have adapter kit for ball joint service on JK’s. The most important piece being the tapered installation cup - perfectly matched the axel C’s on my JK and the ball joints pressed in straight and true. Note: this kit is perfect for replacing standard ball joints. I was pressing in offset ball joints (1.5°) to correct my JK’s camber angle. This kit was a must for it, however I also needed to combine a few pieces from this and the kit that my ball joint press came with.(AURELIO TECH 10PCs Ball Joint... https://www.amazon.ca/dp/B082LQWM7N?ref=ppx_pop_mob_ap_share)Make sure your forcing screw is liberally lubricated, and Bobs your uncle!ADDITIONAL TIP FOR JEEP JK BALL JOINTS:The drivers side was a breeze and the press has good clearance above the steering knuckle.The passenger side took extra effort due to clearance issues for the ball joint press. (Top of spring seat interferes with the top of the forcing screw due to the angle of my Jeeps axel C’s(** which were slightly bent - hence the camber adjustment**)What ended up working was jacking up the opposite end of the Axel by the lower control arm mount (driver side), and removing the lower bolts holding the shock, and the sway bar linkage on the passenger side. This allowed the axel to drop further and the angle of the Axel C changes enough to give clearance for the forcing screw/ ball joint press.If you use this method make sure the weight of the axel does NOT hang on the break line/Wheel speed sensor cable!

T**R

Made it easy!

Definitely made the job easier. Make sure you take a moment to have everything lined straight. I watched a video on YouTube that explained extraction and insulation.

A**N

Worked great

Used this for my jeep, worked amazingly! Very happy

Trustpilot

2 days ago

1 month ago

2 months ago

1 week ago